High Precision Injection YH-330

Highlights

.Design optimization, shorten the length of the clamping part, and increase the support weight of the mold by 15%

.Optimization of the movement curve of the clamping mechanism and the design of the injection dual-line rail, making the machine operation more stable, reliable and durable

.A new generation of servo power system, ultra-high response, the highest pressure can be reached at the fastest 28ms

Logistics & Environmental Protection

With the implementation of smart warehousing logistics, municipal factory construction, sponge city engineering and other projects, it has brought great room for development in the fields of logistics and environmental protection. Whether in professional logistics fields such as pallets and turnover boxes, or environmental protection fields such as trash cans, septic tanks, and purification tanks, we can always provide you with a series of flexible, economical, and adaptable professional solutions.

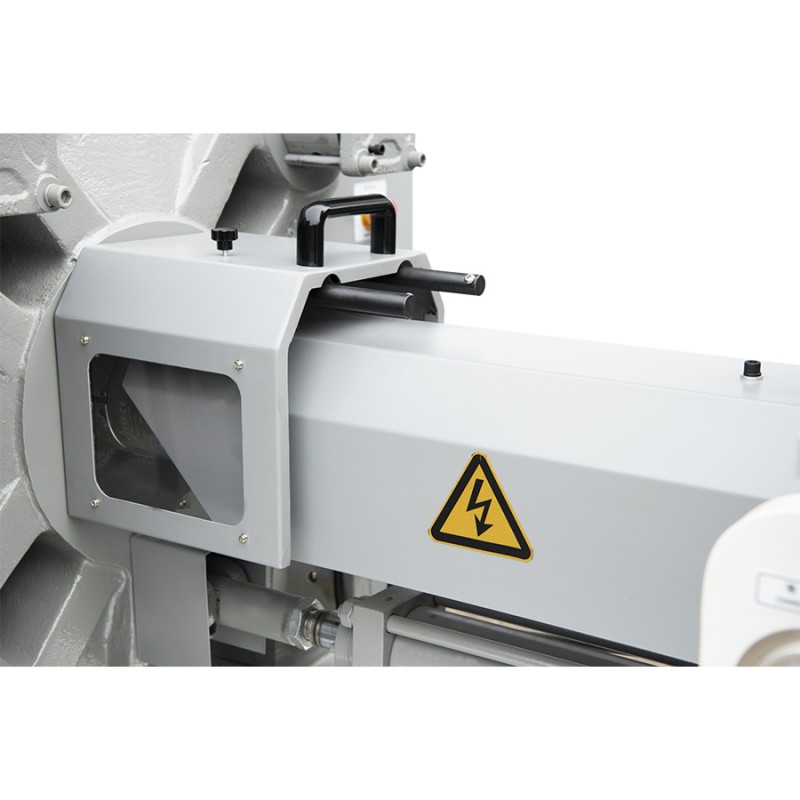

Quality control of injection molding machine

This is a QC team that controls the quality of machinery, hydraulics, electronics, etc. Our goal is to become a world-class supplier of injection molding.

| Specification | Unit | YH-330 |

| Injection Unit | ||

| Screw Diameter | мм | 60 |

| 65 | ||

| 70 | ||

| Screw L/D Ratio | L/D | 21.7 |

| 20 | ||

| 18.6 | ||

| Shot Volume | см3 | 990.5 |

| 1162.5 | ||

| 1348.2 | ||

| Shot Weight (PS) | g | 931.1 |

| 1092.7 | ||

| 1267.3 | ||

| Injection Pressure | Mpa | 213 |

| 182 | ||

| 157 | ||

| Injection weight(PS) | g/s | 211.5 |

| 248.2 | ||

| 287.9 | ||

| Plasticizing capacity (PS) | g/s | |

| 53.7 | ||

| 64.8 | ||

| 81.3 | ||

| Scew speed | rpm | 225 |

| Clamping unit | ||

| Clamping stroke | KN | 3300 |

| Platen stroke | мм | 640 |

| Space Between Tie-bars | мм | 680*680 |

| Max. Mould Thickness | мм | 680 |

| Min. Mould Thickness | мм | 250 |

| Ejector Stroke | мм | 162 |

| Ejector Force | KN | 70.7 |

| Other | ||

| Pump Motor Power | Kw | 37 |

| Heating Power | KW | 20.8 |

| Oli Tank Volume | L | 409 |

| Machine Dimension | M | 7.01*1.7*2.15 |

| Machine Weight | T | 13.3 |