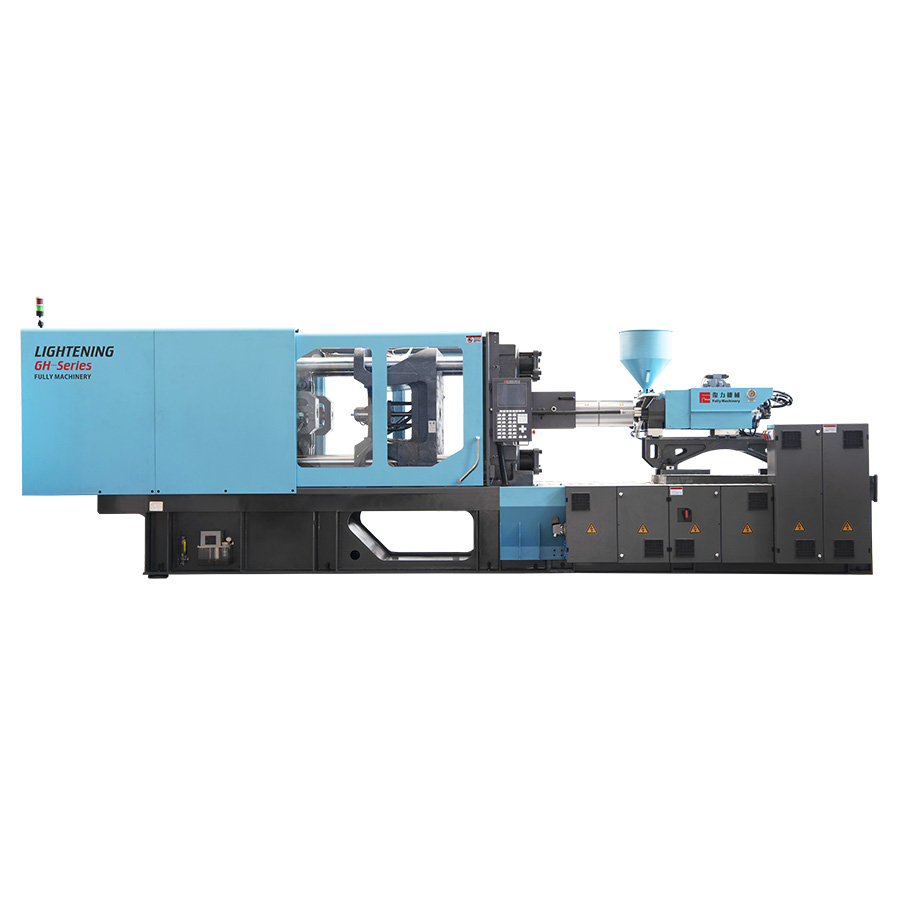

OEM manufacturer Energy Saving Injection Molding Machine - Thin Wall High Speed Injection GH-210 – Beilun

OEM manufacturer Energy Saving Injection Molding Machine - Thin Wall High Speed Injection GH-210 – Beilun Detail:

Quality control of all externally purchased parts

We are extremely rigorous in the selection of suppliers. 90% of the procurement of hydraulic components and electrical components comes from world-renowned brands. At the same time, for these components, we can promise at least one year of quality assurance.

Wide variety of physical tests

Various physical tests are performed on screws, barrels, wall panels and tie rods. Before performing precision machining, our relevant quality inspectors must check the hardness and flaw detection. At the same time, it will also check whether the hardness is consistent.

Quality control of injection molding machine

This is a QC team that controls the quality of machinery, hydraulics, electronics, etc. Our goal is to become a world-class supplier of injection molding.

|

Project |

Project name |

unit |

GH210 |

|

Injection unit |

SCREW DIAMETER |

mm |

45 |

| INJECITON STROKE |

mm |

225 |

|

| SCREW L/D RATIO |

L/D |

25 |

|

| SHOT VOLUME(THEORETICAL) |

CM3 |

358 |

|

| INJECTION WEIGHT(PP) |

g |

322 |

|

|

oz |

11.36 |

||

| INJECTION PRESSURE |

Mpa |

157 |

|

| DWELL PRESSYRE |

Kg/cm³ |

1599 |

|

| NJECTION SPEED |

mm/sec |

380 |

|

| INJECTION RATE |

cm³sec |

496.5 |

|

| SCREW SPEED |

rpm |

400 |

|

|

clamping unit

|

CLAMP FORCE |

Kn |

2100 |

| OPEN STROKE |

mm |

490 |

|

| SPACE BETWEEN TIE BARS(V×H) |

mm×mm |

520×520 |

|

| MAX.MOULD HEIGHT |

mm |

550 |

|

| MIN.MOULD HEIGHT |

mm |

210 |

|

| EJECTOR STROKE |

mm |

150 |

|

| EJECTOR FORCE |

Kn |

61.5 |

|

| EJECTOR NUMBER |

N |

5 |

|

|

others |

MAX.PUMP PRESSURE |

Mpa |

23 |

| PUMP MOTOR POWER |

Kw |

61.8 |

|

| HEATING POWER |

Kw |

15.05 |

|

| MACHINE DIMENSION(L*W*H) |

M×m×m |

5.74×1.45×1.78 |

|

| OILTANK CUBAGE |

L |

300 |

|

| MACHINE WEIGHT(ESTIMATE) |

T |

8.3 |

Product detail pictures:

Related Product Guide:

We thinks what customers think, the urgency of urgency to act in the interests of a customer position of principle, allowing for better quality, lower processing costs, prices are more reasonable, won the new and old customers the support and affirmation for OEM manufacturer Energy Saving Injection Molding Machine - Thin Wall High Speed Injection GH-210 – Beilun , The product will supply to all over the world, such as: Croatia, Turkey, Portugal, We have top engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.